Our services

Play Video

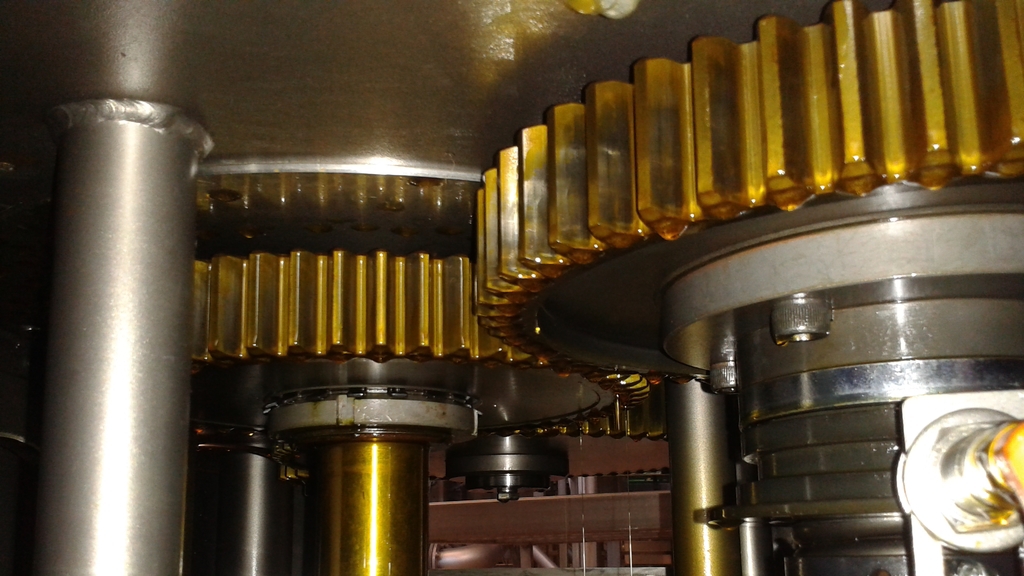

In order to guarantee our clients a good seam on their cans DVS Seamtech makes sure that the machines are perfectly adjusted and optimally maintained so that production can continue with minimal down time.

At DVS Seamtech we stress proactivity and transparency so that you can confidently rest assured that we’ll take care of:

- The assessments, the seamer adjustments, and the compliance.

- Height and diameter conversions for the can and lid.

- Creating a customized maintenance plan with respect to periodic and predictive maintenance.

- Full- and partial-revisions

- Interim inspections, machine and seam process checks.

- Minimizing production interruptions:

- guarantee that the machine continues working optimally;

- Fast identification and troubleshooting of problems and abnormalities in case of unexpected production down time.

- Urgent repairs

- With matching installation and recommendations, delivery of:

- Spare parts (Imeta & others)

- Imeta seam tooling (chucks, rolls & assembly) for practically every type of machine in Can making, Food & Beverage.

- Second-hand (revised) can seamers and fillers.

Click on the YouTube video. The simple film shows you how the seam (sealing) of the cans is formed.

In order to guarantee our clients a good seam on their cans DVS Seamtech makes sure that the machines are perfectly adjusted and optimally maintained so that production can continue with minimal down time.

At DVS Seamtech we stress proactivity and transparency so that you can confidently rest assured that we’ll take care of:

- The assessments, the seamer adjustments, and the compliance.

- Height and diameter conversions for the can and lid.

- Creating a customized maintenance plan with respect to periodic and predictive maintenance.

- Full- and partial-revisions

- Interim inspections, machine and seam process checks.

- Minimizing production interruptions:

- guarantee that the machine continues working optimally;

- Fast identification and troubleshooting of problems and abnormalities in case of unexpected production down time.

- Urgent repairs

- With matching installation and recommendations, delivery of:

- Spare parts (Imeta & others)

- Imeta seam tooling (chucks, rolls & assembly) for practically every type of machine in Can making, Food & Beverage.

- Second-hand (revised) can seamers and fillers.

Click on the YouTube video. The simple film shows you how the seam (sealing) of the cans is formed.

Play Video